Cut with Confidence.

Precision Diamond Blades.

UK-manufactured diamond blades and cutting discs engineered for construction professionals. From concrete to ceramics, PDP blades deliver fast, clean cuts every time.

- Free Next-Day DeliveryOn orders over £30

- Authorised StockistFull product range

- 2 Kent LocationsRamsgate & Canterbury

- Trade Support01843 210 459

British-Made Diamond Blades for Professionals

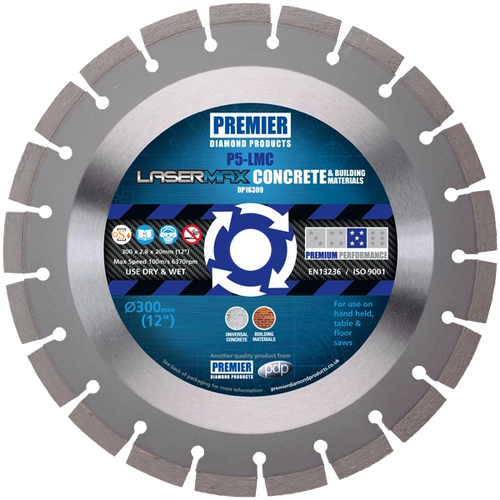

Premier Diamond Products (PDP) is a UK manufacturer of professional diamond blades, core drills and cutting discs. Every PDP blade is engineered and manufactured in Britain to ISO 9001 standards, with EN 13236 compliance ensuring safe, consistent performance on every cut.

From general-purpose blades for angle grinders to specialist segmented and turbo blades for floor saws and wall chasers, PDP covers every cutting application. Their application-matched blade selection means you always get the right blade for the material — whether it's concrete, ceramics, asphalt, granite or brick.

Where PDP Blades Cut

Application-matched diamond blades for every material and method

Top Products from PDP

The diamond blades professionals reach for on every job

BESTSELLER

BESTSELLER

P6-TWC Triple-Disc Wall Chasing Blade

Designed for fast, precise cutting of cable and pipe chases in concrete, block and masonry, the blades' offset triple-disc design produces a 30 mm-wide channel in a single pass, saving time and reducing the need to chisel out the centre of the chase manually.

- Universal 22.23 mm Bore

- Dust Control Compatible

- High-Performance Segments

- Triple-Disc Offset Design

POPULAR

POPULAR

Wet Diamond Cores

Premium wet diamond cores designed for drilling into concrete & reinforced concrete using suitable diamond drilling machines that run at appropriate speeds.

- Easy start diamond crowns

- Turret designed segments.

- Can be used on hard natural stones.

- 200mm to 500mm sizes

Why Professionals Choose Premier Diamond Products

UK-made diamond blades engineered for performance and value

British Made

Every PDP blade is manufactured in the UK. British engineering, British quality control and British jobs — supporting UK manufacturing.

9001 Certified

PDP's manufacturing facility operates under ISO 9001 quality management. Every blade is tested and certified before it leaves the factory.

13236 Compliant

All PDP blades meet EN 13236 — the European safety standard for diamond cutting tools. Maximum peripheral speed ratings are clearly marked on every blade.

Application Matched

PDP engineers blades for specific materials — concrete, tile, asphalt, masonry, granite. The right diamond concentration and bond for every application.

Trade Pricing

Professional-quality diamond blades at competitive trade prices. PDP delivers performance that rivals premium European brands at a fraction of the cost.

Blade Specifications

Over 100 blade specifications covering every diameter, bore size and application. Whatever you're cutting, PDP has the blade for the job.

Explore the PDP Range

From diamond blades to core drills and cutting discs

Diamond Blades

Segmented, turbo and continuous rim diamond blades for concrete, masonry, tile, asphalt and multi-material cutting.

Shop Now

Core Drills

Diamond core drills for clean, precise holes in concrete, masonry, brick and reinforced materials.

Shop Now

Cutting Discs

Abrasive cutting and grinding discs for metal, stone and general-purpose construction applications.

Shop Now

PDP Diamond Blades in Action

See how PDP diamond blades cut through concrete, masonry and ceramics with precision and speed.

- Fast concrete cutting

- Clean tile finishing

- Long blade life

- UK manufactured quality

Diamond Blade FAQs

Common questions about PDP diamond blades and cutting discs

Which diamond blade should I use for concrete?

For general concrete, use the PDP P5-C turbo segmented blade — it's designed for cured and reinforced concrete. For green (uncured) concrete, use the P5-CG green concrete blade which has a softer bond. For heavy reinforcement, choose a blade rated for reinforced concrete with a higher diamond concentration.

What is the difference between wet and dry cutting?

Dry cutting is more convenient — no water supply needed — but generates more dust and heat. Wet cutting keeps the blade cool, extends blade life significantly and suppresses dust. For porcelain tiles, wet cutting is essential. For concrete and masonry, both methods work but wet cutting gives better results and longer blade life.

What does the maximum peripheral speed rating mean?

The maximum peripheral speed (MPS) is the maximum safe operating speed of the blade, measured in metres per second. It's determined by the blade diameter and the RPM of your tool. Never exceed the MPS rating — it's printed on every PDP blade. EN 13236 requires all diamond blades to display this rating.

Can I use a diamond blade on metal?

Standard diamond blades are not designed for metal cutting — the steel in metal clogs the diamond segments. For reinforced concrete (concrete with steel rebar), use a blade specifically rated for reinforced concrete. For cutting metal pipes or steel, use an abrasive cutting disc instead.

What sizes of diamond blade do you stock?

We stock PDP diamond blades in all common sizes: 115mm, 125mm, 150mm, 180mm, 230mm, 300mm and 350mm diameters. Bore sizes include standard 22.23mm and 25.4mm with reducing bushes available. Contact us if you need a specialist size.

Do you offer trade pricing on PDP blades?

Yes. We offer competitive trade pricing across the full PDP range. Contact our trade team on 01843 210 459 for volume discounts and trade account enquiries. We also offer free next-day delivery on all orders over £30.